Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation.

What we do

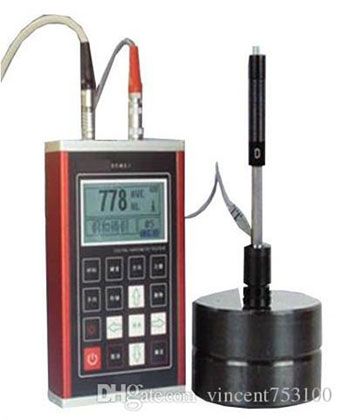

Hardness Tests are extensively used to characterize a certain material, and to identify if it is appropriate for its intended purpose. All Hardness Tests involve the utilization of a particularly shaped indenter that is harder than the material under testing. The indenter is pressed onto the test surface with the use of a certain amount of force. The size of the depth of the indent is measured in order to determine the hardness value.

Benefits of Hardness tests:

- The Hardness Test is easy to conduct

- Results can be obtained within 30 seconds

- Tests are relatively cost-effective

- Finished components can be subjected to testing without being damaged

- Any shape and surface size can be subjected to testing

The major applications of Hardness Tests are to verify the type of heat treatment to be used on a part, and to identify if a material possesses the required properties for it’s intended use. This makes Hardness Tests beneficial in industrial applications.

The five most common hardness scales are:

- Knoop

- Vickers

- Rockwell

- Brinell

- Shore

Our service system

All our Hardness Testers are Calibrated and tested before each shift.

Our commitment

Is always to provide a precise and thorough inspection according to the Client’s requirement.

Most popular Questions

What is Brinell’s hardness test?

Brinell Hardness (BH) Test. Method of measuring the hardness of a material by pressing a chromium-steel, or tungsten-carbide ball (commonly one centimeter or 0.4 inch in diameter) against the smooth material surface, under standard test conditions (generally between 300 to 3 000 kilograms of force for 5 to 30 seconds).

What is hardness testing?

Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation. The Rockwell Test is generally easier to perform, and more accurate than other types of Hardness Testing Methods.

How do hardness testers work?

A Hardness Test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by measuring the depth of indenter penetration, or by measuring the size of the impression left by an indenter.

Benefits of working with us

Based on experience we will always attempt to find an acceptable solution for any unconventional circumstances and needs.

Our Brochure

Our full Company Profile and Service Delivery, can also be viewed in our Brochure.

Download PDF